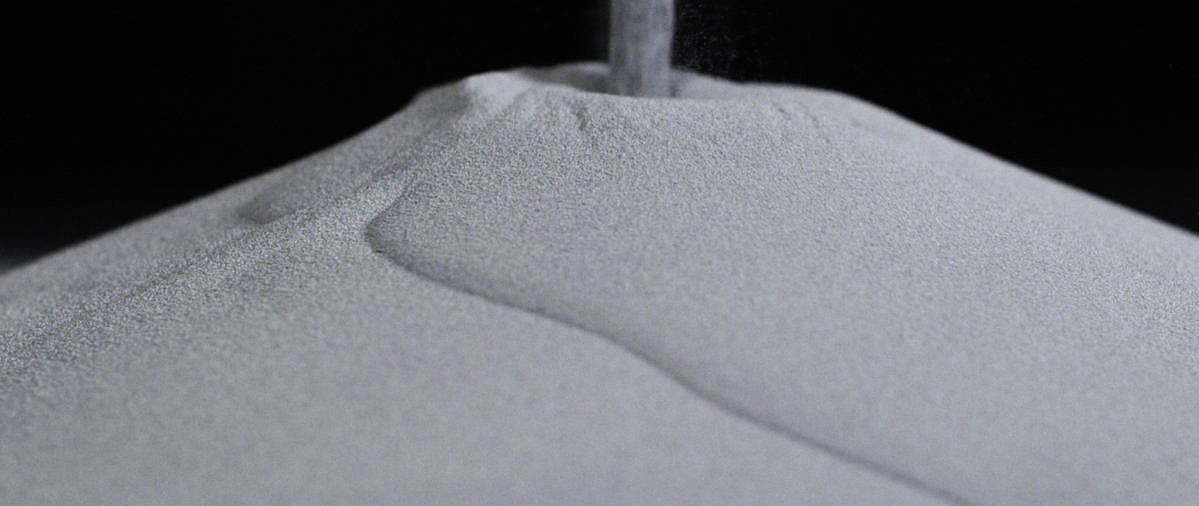

Quality standard of aerated aluminum powder

There are many classifications of aerated aluminum powder. Different

types have different precision ranges, and their use and performance are

very different. Aerated aluminum powder should be used for special

purposes, so it has strict quality requirements. The activity rate of

aerated aluminum powder is As well as the fineness of the product, the

appearance and shape, as well as the overall physical and chemical

reactions, they must meet the relevant standards. The following is a

detailed introduction.

Detailed explanation:

1. Active aluminum of aluminum powder: The amount of air generated by

aluminum powder determines the amount of aluminum powder used in aerated

concrete. The amount of gas generated by aluminum powder refers to the

volume of hydrogen produced by a unit mass of aluminum powder that fully

reacts with water in a standard state. 1g of metallic aluminum has a

theoretical gaseous volume of 1.24L under standard conditions, while

industrial aluminum powder contains a small amount of impurities, and

some aluminum is oxidized into alumina, which makes the actual gaseous

volume of aluminum powder lower than the theoretical value.

2. The fineness of aluminum powder: The fineness of aluminum powder

does not affect the amount of gas generation, but it affects the rate of

gas generation. The finer the aluminum powder, the larger the specific

surface area, and the larger the surface area involved in the reaction,

so the gas generation starts earlier. The speed is fast, and the end of

the breath is also early. In the production process, aluminum powder

needs to have stricter quality control, and its fineness is usually

controlled within a certain range. Some manufacturers and production

processes are different, and the actual fineness still fluctuates

greatly, which will cause aerated concrete The stability of pouring

becomes worse.

3. Particle shape of aluminum powder: The shape of aluminum powder has

an important effect on the gas generating characteristics of aluminum

powder. The shape of aerated concrete is required to be ground

broad-leaved or irregular scaly. The ground aluminum powder particles,

It forms a flat thin scaly shape with a larger new metal surface,

thereby increasing the area of gassing reaction.

4. The gas evolution rate of aluminum powder: The above introduced the

physical and chemical properties of aluminum powder quality standards.

Whether the physical and chemical properties of aluminum powder meet the

needs of the production of aerated concrete must be reflected in the

gas expansion process of the slurry. Therefore, the determination of the

gas evolution process of aluminum powder in the slurry can make a

comprehensive evaluation of its performance.

5. Water dispersibility of aluminum powder: aerated aluminum powder is a

hydrophilic metal aluminum powder, which is suspended in an aqueous

solution in water. When aluminum powder is added to the slurry, the

better the water dispersibility, the more soluble in water, and the gas

reacts. It can be done as soon as possible. Some aluminum powder

manufacturers use some aluminum products that contain oil or other

water-insoluble impurities to produce aerated aluminum powder, which

will cause water-insoluble substances on the surface of the aluminum

powder, resulting in water dispersion of the aluminum powder It has poor

performance, does not disperse in the slurry, and agglomerates, which

eventually leads to unsmooth gassing and affects pouring quality.