In ancient Egypt, artisans beat and stretched gold into gold leaf, and

put it on stones, bones, etc., to make crafts or sacrifices. In the

above process, the edges of the gold foil are easy to break and fall

off, resulting in some gold fragments. Later, craftsmen discovered that

mixing these debris with natural oils and coating them on these objects

can also achieve a decorative effect. Soon these discoveries and

technologies were transferred to silver. Over time, this technology was

also transferred to ancient India, China, and later to Europe. With the

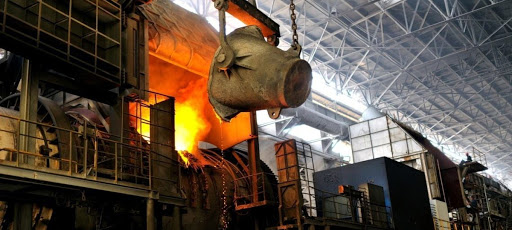

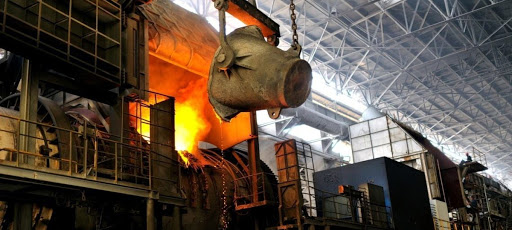

development of metal smelting technology, metallic aluminum appeared. It

was found that aluminum is relatively soft in texture and has good

ductility, that is, it can be rolled into flakes by pressure. This is a

very important prerequisite for the production of aluminum pigments.

During the Renaissance in Europe, aluminum pigments were produced by

mechanical ramming. Even using a rigid hammer, hammer the aluminum block

on the steel plate into a sheet. During processing, grease is used as a

lubricant. However, the efficiency of this process is not high, there

is a danger of explosion, and the performance of the product is not

satisfactory.

In 1892, the German Schlenk Company began to produce aluminum powder.

In 1910, Alcoa began producing aluminum pigments for coatings.

In 1930, Professor E.J.HALL of Columbia University in the United States

invented the wet grinding process for the production of aluminum

pigments. The method is to use a roller ball mill to add a certain

amount of steel balls, granular aluminum, solvents and fatty acids. Turn

on the ball mill and grind at a certain speed. Using the impact and

shear force generated by the movement of the steel ball, the aluminum

powder is first stretched into flakes, and then crushed to a certain

degree of fineness (particle size). Due to the presence of solvents,

aluminum is isolated from contact with oxygen in the air, thereby

playing a protective role and avoiding explosion hazards. At the same

time, the output and quality of products have been greatly improved.

Therefore, wet ball milling has gradually become a metal pigment. The

main preparation process. Up to now, the world's major metal pigment

manufacturers have adopted this process.

In 1934, since the Chrysler Automobile Company of the United States

first used aluminum pigments in automobile coatings, the technology and

output of metallic pigments have been greatly improved. At present, with

the advancement of metallic pigment technology, more than 50% of

automobiles in the world are painted with metallic flash paint. Among

them, more than 75% in the United States and more than 50% in Japan and

Europe contain aluminum pigments. For household and office appliances

such as televisions, computers, refrigerators, and mobile phones,

aluminum pigments are used in a larger proportion and become a trend.

From magnificent ancient palaces to modern high-rise buildings, from

cars on the streets to people’s daily necessities, products with

metallic luster can be seen everywhere, but many products with metallic

luster are not real metal products. The emergence of metallic paint

(aluminum pigment occupies a large proportion of metallic pigments) has

made up for the lack of people's pursuit of metallic luster, which not

only reduces the cost, but also meets the demand. Solvent-based metallic

paint has excellent luster and excellent weather resistance. ,

Corrosion resistance, widely used in industries such as automobiles,

motorcycles, bicycles, ships, toys, home appliances, computers and

mobile phones. Therefore, under the impetus of the market, the

development of aluminum pigments is unstoppable, and the market prospect

is very broad.