①Direct grinding: Add dispersant and antioxidant to the aluminum powder

raw material, and then use water-soluble solvent to grind directly in

the ball mill. Advantages and low cost. Disadvantages: The production

process is dangerous and the effect is average. For example: poor

corrosion resistance, unstable, etc.

② Replacement by oily silver paste is also called oil-to-water

replacement. Use high-boiling water-soluble solvents (such as ethylene

glycol butyl ether) to replace the mineral spirits by distillation, and

add some dispersants and antioxidants.

Advantages: A good metallic appearance of aluminum silver paste can be

obtained. Disadvantages: poor corrosion resistance, unstable, poor

versatility. The first two are only low-end primary products that rely

on some high-molecular materials to physically adsorb on the surface of

the silver paste to prevent the erosion of some water and impurities.

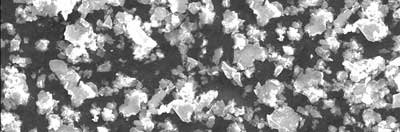

③Compared with the first two, the universal method that is recognized

internationally and has a better effect is to coat the surface of the

aluminum powder with surface silica (also called nano-silica surface

deposition coating). Covered with a dense protective film with a

thickness of 50-100 nanometers, which adsorbs the deposited film of

nano-silica particles on the surface of aluminum powder through a

chemical reaction to prevent corrosive substances such as water, acid

radical ions, alkaline ions, oxidants, etc. erosion. Advantages: get

better results, higher acid and alkali resistance, and stability.

Disadvantages: high cost. To carry out degreasing, and the chemical

reaction operation of silica deposition coating. In addition, chemical

equipment such as reactors is also used. The diameter of the nano-silica

particles is about 10-30 nanometers. The better the reaction control,

the smaller and uniform the nano-particles, and the denser the

protective film made, and the better the effect.

For example: Taking the high-end water-based aluminum silver paste

produced by our group as an example, in order to obtain the best overall

effect, the coating film as a whole is roughly divided into a

three-layer film structure. Bottom layer: Passivation film structure,

which has the effect of pretreatment and surface activation.

Intermediate layer: the key dense film structure of nano-silica. Surface

layer: surface modification of polymer organic materials for better

dispersion, leveling, and orientation.

On this basis, different directional arrangement effects such as

floating silver, immersed silver and suspension can also be obtained

through different modification methods.

2. How to test the difference between water-based aluminum and silver

paste? That is, how to identify the advantages and disadvantages of

water-based aluminum silver paste, such as: corrosion resistance, etc.,

to prevent bad businesses from shoddy. This requires alkali resistance

testing. Reason: For water-based paints and water-based paints, their

systems are weakly alkaline, because normal polymer resins are

lipophilic, so making water-based is the process of changing resin oil

to water. It needs to be hydrophilic. In order to achieve this, it is

necessary to graft hydrophilic hydroxyl, amino or carboxyl groups on the

polymer material. This type of modified group is alkaline, so the resin

produced is generally weakly alkaline, so we need to conduct an

alkaline resistance test.

Quick test: Directly perform the strong alkali resistance test. First,

configure the test solution: 1.2% sodium hydroxide solution, pH value

between 14 ± 0.1, and temperature maintained at about 25 ℃.

Reaction equation: 2H2O+2Al+2NaOH==2NaAlO2+3H2

Then, about 2 grams of water-based aluminum silver paste was diluted

with 4 grams of clean water and then poured into 100 ml of test solution

to test the length of time it can stabilize in the test solution. This

method can directly distinguish whether the production process is

oil-to-water or direct grinding, or high-end silica-coated water-based

aluminum silver paste. If it is not covered with a silicon dioxide film,

it will usually start to react within 1 minute, the reaction is

violent, and it will generate a lot of gas and generate heat. If it is

coated with silica, it can be stable for about 3 minutes if it is poor

in China, and it can be stable for 5 minutes to 20 minutes.

If the stabilization time can reach more than half an hour, the alkali

resistance effect obtained will be even better. For now, the benchmark

product in the water-based silver paste market is the water-based

aluminum silver paste produced by the German Aika Company. Its products

can generally get a stable time of about one hour when tested in the

test solution. In addition, the aqueous aluminum silver paste coated

with silica can generally be used in summer. On the contrary, the

water-based aluminum-silver paste processed by other processes will have

adverse reactions such as heat generation and flatulence during

transportation in summer. If the test stability can reach more than half

an hour, the storage period can reach 1-2 years. For products that take

less than half an hour, the shelf life is only three months to six

months. Of course, the degree of alkalinity (pH level) in the

water-based paint and the water-based paint itself also has a certain

impact on the storage period.