The technology of aluminum pigments is still in continuous progress.

Its current technical development focuses mainly on water-based and

coating modification. In addition, it improves pigment fineness, shape

regularity, particle size uniformity, product quality stability and

other physical properties. Indicators, improvement of pigment dispersion

and other properties, research and development of color aluminum

pigments, special functional aluminum pigments, etc. are also its

technological development trends.

1. Water-based product (water-based aluminum pigment)

Untreated aluminum pigments will chemically react with water to produce

a large amount of hydrogen, which will destroy the metallic luster of

aluminum particles, which will seriously affect their weather

resistance. Therefore, the quality of water-based aluminum pigments and

their application fields and production processes, especially coatings

The process is closely related. The organically treated products have

good water resistance, very low gas release and excellent weather

resistance; the inorganically treated products have a thinner coating

layer, which can effectively display the metallic luster of aluminum

pigments. Water-based aluminum pigments are one of the inevitable

development directions of the aluminum pigment industry. Although

international companies have nearly 60 years of experience in this

field, the research and development of new products has not stopped.

2. Low pollution in production process

In addition to water-based aluminum pigments, domestic companies also

need to develop production processes towards low pollution. Many

domestic enterprises used 200# solvent oil for grinding before 2009, and

used high-boiling trimethylbenzene and tetramethylbenzene as the final

solvent of aluminum silver paste. The aromatic hydrocarbons contained in

these solvents are especially high-boiling trimethylbenzene and

polycyclic tetramethylbenzene. Aromatic hydrocarbons are harmful to the

human body and the EU has banned them by legislation. At present, most

companies have adopted alkane solvents, such as high boiling point

dearomatized hydrocarbon solvents D60, D70, and D80. However, the

storage stability of aluminum pigment products and the compatibility of

coatings still need to be improved, and a certain proportion of

assistance is often required. Solvent.

3. Colorization of aluminum pigments

Another development trend of aluminum pigments is to form color effect

aluminum pigments through surface coating modification. Color aluminum

pigments not only have the original metallic luster of aluminum

pigments, but also have bright colors. Because the color aluminum

pigment has bright colors, strong corrosion resistance, good insulation,

not easy to fade, and strong metallic luster, it has a wide range of

application development prospects.

In 2010, BASF launched a new generation of

PaliocromBrilliantOrangeL2850 color aluminum pigments, which can display

color effects from orange to red. The product uses SiO2 and iron oxide

coated aluminum flakes, which contain 40% to 60% aluminum and 25% to

45%. Naphtha, 10% to 20% iron oxide and 1% to 5% silicon dioxide. The

product has a good flashing effect and high hiding power, and is

suitable for solvent-based and water-based systems. It is mainly used

for high-performance automotive coatings and industrial coatings for

consumer electronic products such as computers and mobile phones. It can

also display more abundant effects together with other effect pigments.

Color effect The coating process of SiO2 and organic pigments can

improve the chargeability of aluminum pigments. Colored aluminum

pigments are also suitable for powder coatings produced by the dry

blending process, but they are not suitable for the current bonding

process, because this process easily causes a large amount of colored

pigments to detach from the surface of the aluminum particles, thereby

causing the loss of specific optical properties.

4. Special functional aluminum pigments

It is the consensus of the industry to continuously expand the

application fields of aluminum pigments. At the end of 2007, Aika

launched an aluminum pigment for laser marking. Laser marking technology

is one of the largest application areas of laser processing. It uses

high-energy-density laser to locally irradiate the workpiece to vaporize

the surface material or cause a chemical reaction of color change,

thereby marking various characters, symbols and patterns. Aika’s

Lasersafe040 aluminum pigment product is a pigment concentrate that can

be used for thermoplastic polyolefins, such as PVC, PET, TPU, and

polycarbonate. The addition amount is only 0.01%, which is very suitable

for YAG laser (yttrium aluminum pomegranate). Stone laser) high-speed

assembly line production, with high-contrast effect, can depict

crystal-like patterns, text, and even photos in the plastic. Unlike

other pigments used for laser marking, this pigment does not contain

heavy metals, so it complies with FDA and European food safety standards

and other regulations, and can be used in many fields such as food

packaging.

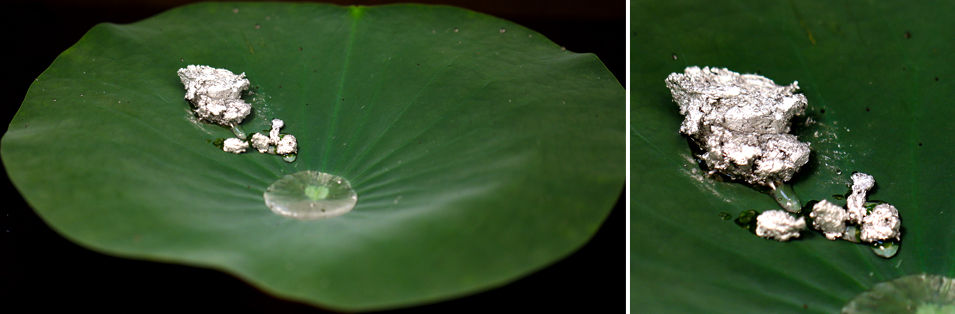

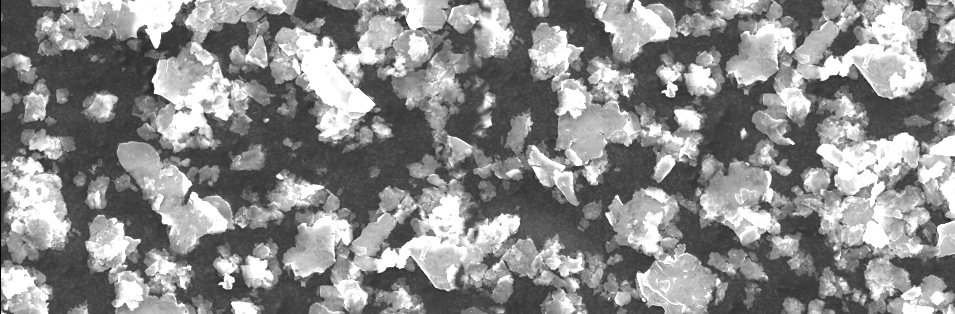

5. Nano aluminum pigment

Nano-flaky aluminum pigments have attracted more and more attention in

recent years. Their diameter and thickness are in the range of

nanomaterials (30-50nm), so the diameter-to-thickness ratio is much

larger than traditional aluminum powder. It has a very strong

reflectivity to light and can be evenly distributed in the paint And it

is almost horizontally distributed, and the protective and decorative

effects produced are significantly better than traditional aluminum

pigments. The current nano-flaky aluminum powder pigments mainly refer

to the aluminum pigments (ie electroplated aluminum pigments) produced

by the physical vapor deposition method (VMPs) process, such as

evaporation-condensation method and sputtering-deposition method, while

laser-induction heating method, Plasma heating method, electron beam

radiation method and other nano aluminum powder production processes are

still in the laboratory stage and have not been industrialized.

6. Improve stability, dispersion and alignment

The stability, dispersion and orientation properties of aluminum

pigments are of great significance to their application effects.

Aluminum is an active metal. In order to improve its stability, it is

often necessary to use an inorganic layer or an organic layer for

coating modification. The coated aluminum pigment can also improve the

shear resistance performance and keep the shape of the scales from being

damaged, which is particularly important in application fields such as

powder coatings and plastics. In addition, the aluminum particles have a

large specific surface area, and the aluminum particles without surface

treatment are easy to agglomerate, and the coated aluminum pigment has

better dispersibility.

Finally, in terms of technology, Chinese aluminum pigment companies

also need to strengthen the research on fatty acids and various

additives used in the production of aluminum pigments to meet the

requirements for the production of high-end aluminum pigments.

Sunflower Aluminum Pigment

Sunflower water-based aluminum paste

Sunflower aluminum paste

Aluminum paste producer

Aluminum powder producer