1. What is aluminum silver paste?

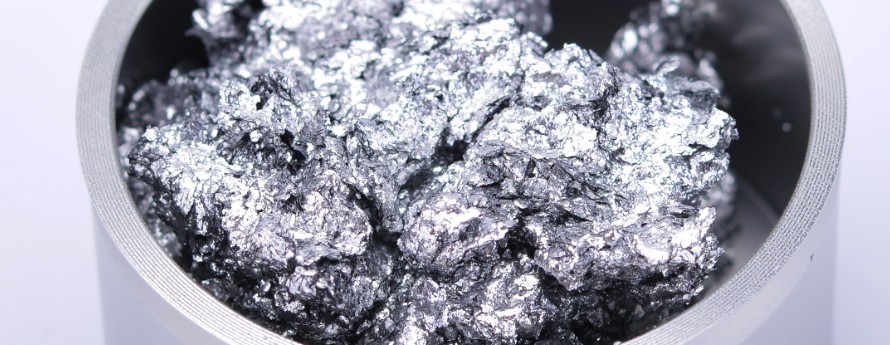

Aluminum-silver paste is a kind of inorganic metal pigment, which is

mainly composed of aluminum flakes, solvents and additives. The ratio is

about 60%-70%: 30%-40%:0-10%. After special processing technology and

surface treatment, the surface of the aluminum sheet is smooth and flat,

the edges are neat, the shape is regular, the particle size

distribution is concentrated, and the matching with the coating system

is excellent. The aluminum-silver paste is mainly in the form of paste

or paste, among which the shapes of aluminum flakes are silver dollar,

snowflake and scaly. The industry uses special terms such as solid

content, particle size, whiteness, brightness, metallicity, hiding

power, and cleanliness to describe the physical properties of aluminum

silver paste. The particle state of the aluminum-silver paste is in the

form of scales. In most processes for producing aluminum silver paste,

lubricants are required to prevent "cold welding". When used in

coatings, these lubricants can impart floating or non-floating

characteristics to the aluminum silver paste.

2. Types of aluminum paste and its coating effect

The main raw materials for preparing floating aluminum silver paste are

atomized aluminum powder, solvent oil and stearic acid (saturated fatty

acid, density: 0.847g/cm3). In the ball milling stage, saturated fatty

acids such as stearic acid are used as lubricants. Stearic acid is

adsorbed on the surface of the aluminum sheet to make the aluminum

silver paste hydrophobic and oleophobic. The aluminum flakes coated with

stearic acid in the coating system cannot be wetted by the base

material, and the density is relatively small, thereby reducing the

downward gravity of the aluminum flakes. On the other hand, with the

upward thrust of the molecules moving to the surface of the carrier when

the solvent volatilizes, the sinking force formed by the weight of the

aluminum sheet is offset to make it float to the surface of the paint

film, and an opaque silver film is formed on and near the surface of the

paint film. Since the aluminum flakes float on the surface of the paint

film, and some of the aluminum flakes overlap, there will be silver

drop, and recoating is also difficult. Floating aluminum silver paste is

generally used for roof coating, maintenance, anti-corrosion coatings,

reflective coatings, and imitation chrome-plating effect coatings that

require high protection. Its appearance varies according to the

thickness of the particles (particle size), which can range from rough,

white appearance to gray, highly reflective or mirror-like effects, and

can produce effects from flat, silver, and high-gloss (chrome-plated).

The coarse-grained floating aluminum silver paste has the lowest hiding

power and rough structure, but it can obtain the whitest and brightest

coating. On the contrary, the fine-grained floating aluminum silver

paste has the greatest hiding power, the smoothest structure and high

reflectivity. These floating aluminum silver paste aluminum sheets have a

smooth surface, which can reflect light (visible light, ultraviolet

light and infrared light), and have good heat insulation effects; the

densely laminated aluminum sheets can also provide shielding effects to

prevent moisture and other reaction media from entering the paint film ,

It has a good protective effect on the coating substrate.

②Non-floating aluminum silver paste and its coating effect

The main raw materials for preparing non-floating silver paste (except

electroplating silver) are atomized aluminum powder, solvent oil, and

oleic acid or erucic acid (unsaturated fatty acid). The non-floating

aluminum silver paste uses unsaturated fatty acid as the aluminum sheet

coating material to make the aluminum sheet have lipophilic and

hydrophobic properties, so the aluminum sheet can be completely wetted

by the oily solvent and resin system, evenly distributed in the entire

paint film, and has The tendency of sinking, so the adhesion is very

good, the coating film is firm and stable, and it can be recoated and

finished (see Figure 2 for the effect). Compared with floating aluminum

silver paste, in terms of surface performance, non-floating aluminum

silver paste can provide a more significant improvement and has a very

good decorative effect. It is widely used in vehicles, furniture,

electronic products, coils, etc. Various occasions, automobile paint,

motorcycle paint, bicycle paint, plastic paint, architectural paint,

ink, mobile phone shell and buttons, electromechanical shell, electric

shell, industrial paint and many other fields. Non-floating aluminum

silver paste can also be generally divided into imitation plating, flash

silver, and fine silver. The average particle diameter of fine silver

is the smallest and the brightness is the lowest; the average particle

diameter of flash silver is the largest and the brightness is the

highest; the average particle diameter of imitation electroplated silver

is between fine silver and flash silver, and the brightness is also

between fine silver and flash silver.

There is also a special effect aluminum silver paste in the

non-floating aluminum silver paste, which is electroplated silver.

Electroplating silver is also called mirror silver, mirror aluminum

silver paste, super bright aluminum silver paste or vacuum aluminum

plating suspension. It is not produced by the HALL ball milling method.

It is a non-floating aluminum silver paste produced by using high-purity

aluminum as raw material and using a unique vapor phase metallized

pigment process (VMPs). The aluminum content is 10%-20%, and the average

particle size is The D50 is between 5-12 microns, the thickness of the

aluminum sheet is nanometer, the surface hiding power and brightness are

great, and the excellent electroplating effect or mirror effect can be

obtained with a small amount.

Electroplating silver can replace electroplating, with little harm,

good hiding power and simple construction. It is widely used in paint

(cosmetic bottle paint, wine bottle paint, plastic paint, car paint) and

printing ink (home improvement glass mirror ink, home appliance glass

mirror ink, Mobile phone lens mirror ink, gravure printing ink for

tobacco and alcohol packages) and many other industries.

3. Precautions for storage of aluminum silver paste

Store in an airtight tank indoors at a storage temperature of 15-40°C

(special attention should be paid in winter or when the ambient

temperature is equal to or lower than 10°C). Avoid direct exposure to

sunlight, rain, or high temperatures; excessive jolts and vibrations

during transportation, and storage under certain conditions may cause

partial separation of aluminum and solvent components. Once it is

unpacked and used, it should be used up as soon as possible. If it

cannot be used up at one time, it should be completely sealed

immediately to prevent the solvent in the aluminum-silver paste from

evaporating. If it is left for too long, please test before use.

What is aluminum silver powder?

Aluminum-silver powder is a deep-processed product of aluminum-silver

paste. It is divided into powder metal pigments produced by dry ball

milling process and wet ball milling and coating treatment process, with

stable quality and excellent weather resistance. Generally, it is

mainly used for thermosetting powder coatings (thermosetting refers to

heating and solidification molding without changing the chemical

structure, and cannot be reversed after molding), outdoor decoration

products, plastic masterbatch and some ink products. The solid content

of aluminum silver powder is very high, so the added amount in the

terminal application is relatively low, from 0.5% to 3% of the added

amount.

What is a silver bar?

Silver bars are mainly used to solidify and strip the paste-like

aluminum silver paste to make it more suitable for the application of

end products, such as high-end inks, injection molding, and color

masterbatches. The principle is very similar to the color masterbatch.

They are all carrier pigments made of aluminum silver paste plus soluble

resin or PE wax and a small amount of additives. Silver bar products

have five major advantages: very few bad odors, safe and environmentally

friendly; good stability, can be stored for a long time; easier to

disperse; almost no solvent, rarely incompatibility with plastic or ink

systems; safe transportation.

Aluminum pigments also have more extended products, such as

environmentally friendly aluminum silver paste, odorless aluminum silver

paste, water-based aluminum silver paste, resin-coated aluminum silver

paste, colored aluminum silver paste, nano-aluminum silver paste and so

on.

Sunflower Aluminum Pigment, Sunflower Chemical Group, Sunflower aluminum paste, Sunflower aluminum powder.