Process characteristics and classification of aluminum paste

Aluminum paste production is a typical industry that is easy to get started and difficult to make. A few ball milling, separation, kneading and filter press equipment can be put into production. This is also the reason why there are many large and small domestic manufacturers. However, articles and books about aluminum paste production are almost blank. Due to the rapid development of the aluminum paste industry in recent years, it has become the most distinctive functional pigment in Asia. It is precisely because of the rapid development of the aluminum paste industry that the global aluminum paste price continues to decline.

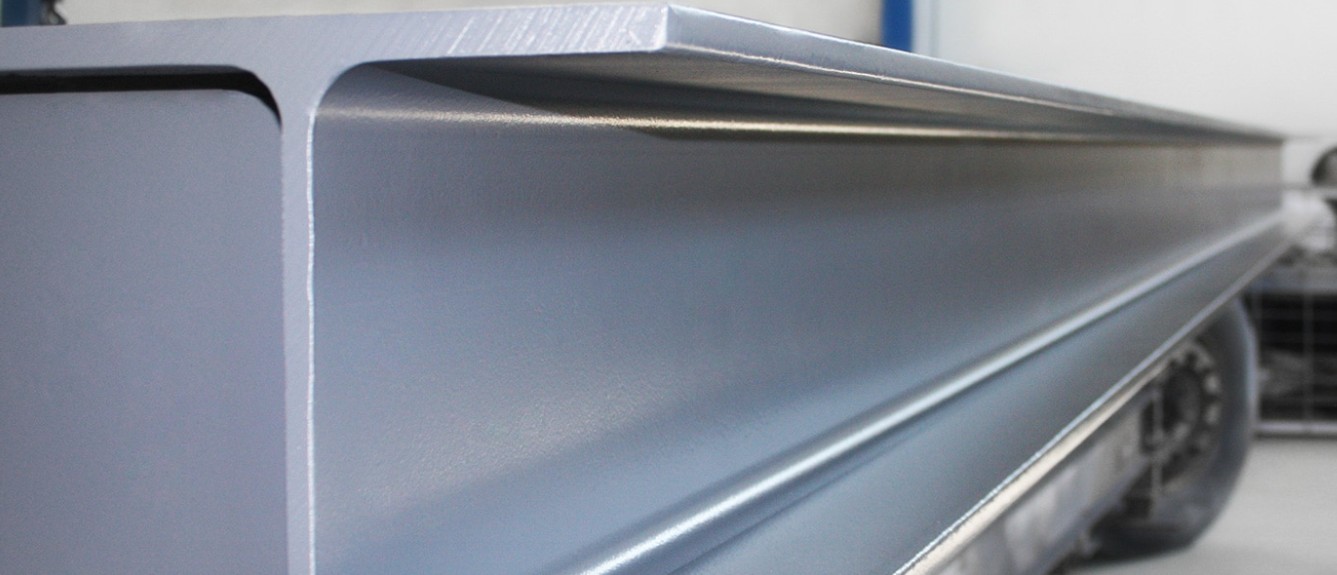

Aluminum paste is a paste-like metallic pigment with a very unique effect that has been treated by a special process. Its main components are aluminum flakes and petroleum solvent treated by a special process. The purity range of aluminum used to make aluminum paste is usually 99.3-99.9%, due to the shape of aluminum flakes such as snowflakes, fish scales and silver dollars. The aluminum paste made of it is characterized by smooth and flat surface of the aluminum sheet, concentrated particle size distribution, regular shape, excellent light reflection ability and metallic luster. It is mixed with transparent color pigments, and the paint film has obvious "different color effect at different angles." , The decorative effect is very gorgeous and beautiful. Mainly used in automotive coatings, weak electrical plastic coatings, metal industrial coatings, marine coatings, heat-resistant coatings, roof coatings, etc.

Classification of aluminum paste

Generally, aluminum paste can be divided into two categories: leafing type and non-leafing type. The two production processes are basically the same, except that the floating type uses stearic acid or saturated fatty acids as grinding aids, while the non-leafing type uses oleic acid or unsaturated fatty acids as grinding aids.

◆Leafing type

In the leafing aluminum paste, the aluminum flakes are aligned near the surface of the paint film to form an opaque silver film. This opaque nature is the main factor that makes the leafing aluminum pigment an important functional raw material. Leafing aluminum pastes are generally used in roof coating, maintenance, anti-corrosion coatings, reflective coatings, imitation plating effect coatings and commercial coatings that require high protection. The appearance of leafing aluminum paste can vary according to the thickness of the particles, from a rough, white appearance to a dark, highly reflective or mirror-like effect. That is to say, it can produce effects such as flat light, silver white, high light (chrome plating) and so on. The coarse-grained leafing aluminum paste has the lowest hiding power and rough structure, but it can obtain the whitest and brightest coating. On the contrary, the fine-grained leafing aluminum paste has the greatest hiding power, the smoothest structure and the high reflective coating.

◆Non-leafing

Non-leafing aluminum paste is uniformly and parallelly distributed throughout the paint film. The appearance of the formed coating film is different from that of leafing aluminum paste. Because it can be mixed with a variety of pigments and is suitable for a variety of systems, it is unique to industrial coatings. Metallic or multi-color effect, with different degrees of glitter and color. However, any pigments or dyes must be transparent when used with non-leafing aluminum pastes in order to achieve a realistic metallic effect. There are many types of non-leafing aluminum pastes, coloring power from low to high, particle size from coarse to fine, appearance from white, shiny to grayer, more delicate, and acid-resistant series products to reduce industrial smoke, acid rain and other adverse environments The impact on coatings.

In the non-leafing category, it can be subdivided into five types according to the shape and processing technology of the aluminum sheet used:

High temperature resistant type medium and fine flash silver series: suitable for coating systems that require high temperature curing. This series of products have a strong flashing effect and a different color effect, moderate hiding power, and excellent dispersion. The product is especially suitable for automotive original paint (OEM), coil coatings and fluorocarbon coatings.

Imitation electroplating series products: It is a fine grade product like silver dollar. Its main feature is that it has a good metallic feeling and covering ability, and has a high whiteness. It is suitable for the coating of plastic products.

Flash silver series: This series of products is divided into two categories: one is coarse flash silver, and the other is medium and fine flash silver.

Coarse flash silver is a traditional product with a high metallic feel, relatively poor hiding power, and a price advantage. It is mainly used for plastic paint.

The medium-fine flash silver is a silver dollar-like product with a concentrated particle size distribution, a more balanced metallic feel and whiteness, and a diameter range of 14-20μm. Used in plastic paint, car refinish paint, etc.

Fine silver series: The typical characteristics of fine silver are higher metallic feeling and better positioning and arrangement ability. The median diameter ranges from 6-15μm. Suitable for plastic paint and ink systems.

Leafing imitation electroplating products: silver dollar-like products, suitable for electroplating effect paint, such as electric cars, bicycles, etc.