Sunflower Chemical explains leafing aluminum paste

Aluminum paste is an inorganic metal pigment, which is mainly composed

of aluminum flakes, solvents and additives. The ratio is about 60%-70%:

30%-40%: 0-10%. After special processing technology and surface

treatment, the surface of the aluminum sheet is smooth and flat, the

edges are neat, the shape is regular, the particle size distribution is

concentrated, and the matching with the coating system is excellent. The

aluminum paste is mainly in the form of paste or paste, and the shapes

of the aluminum flakes are silver dollar, snowflake and scaly. The

industry uses special terms such as solid content, particle size,

whiteness, brightness, metallicity, hiding power, and cleanliness to

describe the physical properties of aluminum paste. The particle state

of aluminum paste is in the form of scales. In most processes for

producing aluminum paste, lubricants are needed to prevent "cold

welding". When used in coatings, these lubricants can impart leafing or

non-leafing properties to the aluminum paste.

The main raw materials for preparing leafing aluminum paste are atomized

aluminum powder, solvent oil and stearic acid (saturated fatty acid,

density: 0.847g/cm3). In the ball milling stage, saturated fatty acids

such as stearic acid are used as lubricants. Stearic acid is adsorbed on

the surface of the aluminum sheet to make the aluminum paste

hydrophobic and oleophobic. The aluminum flakes coated with stearic acid

in the coating system cannot be wetted by the base material, and the

density is relatively small, thereby reducing the downward gravity of

the aluminum flakes. On the other hand, with the upward thrust of the

molecules moving to the surface of the carrier when the solvent

volatilizes, the sinking force formed by the weight of the aluminum

sheet is offset to make it float to the surface of the paint film, and

an opaque silver film is formed on and near the surface of the paint

film. Since the aluminum flakes float on the surface of the paint film,

and some of the aluminum flakes overlap, there will be silver drop, and

recoating is also difficult.

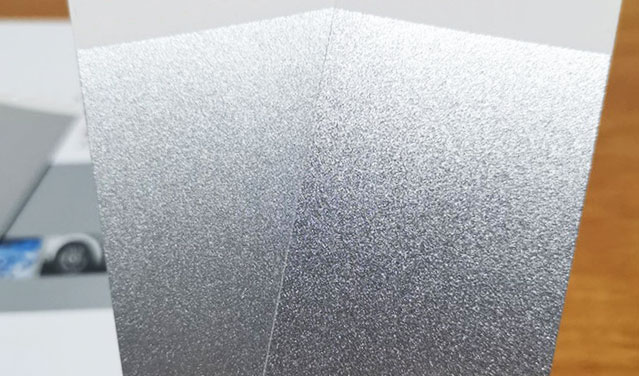

Leafing aluminum pastes are generally used for roof coating,

maintenance, anti-corrosion coatings, reflective coatings, and imitation

chrome effect coatings that require high protection. Its appearance

varies according to the thickness of the particles (particle size),

which can range from rough, white appearance to gray, highly reflective

or mirror-like effects, and can produce effects from flat, silver, and

high-gloss (chrome plated).

The coarse-grained leafing aluminum paste has the lowest hiding power

and rough structure, but it can obtain the whitest and brightest

coating. On the contrary, the fine-grained leafinging aluminum paste has

the greatest hiding power, the smoothest structure and high

reflectivity. These leafing aluminum paste aluminum sheets have a smooth

surface, which can reflect light (visible light, ultraviolet light and

infrared light) and have good heat insulation effects; the densely

laminated aluminum sheets can also provide shielding effects to prevent

moisture and other reaction media from entering the paint film. Play a

good protective effect on the coating substrate.